Banana Chips Drying Production Line Factory Customization

The banana drying production line is a fully automatic production line that integrates cleaning, peeling, slicing, drying and packaging. The banana dried production line uses advanced hot air drying technology to efficiently transform fresh bananas into sweet and crispy industrial-grade dried bananas. Dried banana chips production line completely solves the pain points of natural drying, such as site limitations, pollution risks, uneven quality and low efficiency, and is the basis for achieving large-scale, standardized and year-round production.

Banana Dried Production Line Processing Flow

1.Peeling

2.Cutting

3.Color Fixation

4.Drying

5.Packaging

- Peeling: Use a banana peeling machine or manual peeling to remove the banana peel. Automatic peeling machines peel the bananas cleanly without damaging the flesh, with high efficiency, and are the first choice for large-scale production.

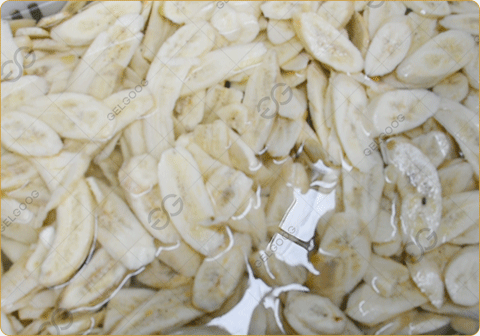

- Slicing: Send the peeled bananas to the banana slicer and cut them into thin slices of uniform thickness. The thickness of the slices can be adjusted as needed, generally 2-5mm. The sliced banana slices should be processed as soon as possible to prevent oxidation and discoloration.

- Blanching: Put the banana slices into the blanching machine for a short heat treatment. Usually the water temperature is controlled at 90℃-100℃ for 1-2 minutes. Blanching can reduce the enzyme activity of the banana slices and prevent them from browning during subsequent processing and storage. At the same time, it can also reduce the microbial content, soften the pulp tissue, and improve the quality and storage resistance of the product.

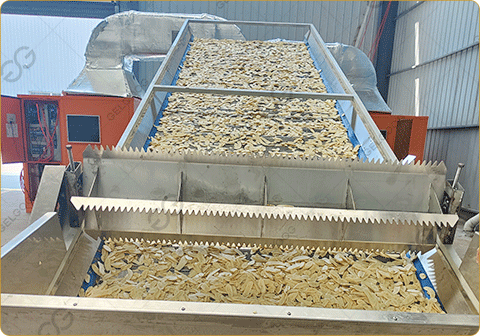

- Drying: Evenly place the blanched banana slices on the drying tray and put them into the banana dryer for drying. The drying temperature and time are set reasonably according to factors such as the thickness and variety of the banana chips. Generally, the initial temperature is controlled at 50℃-60℃, and the later temperature is controlled at 60℃-65℃. The drying time varies from 18 to 24 hours, so that the moisture content of the banana chips can be reduced to about 15% – 20%.

Banana Drying Production Line Advantage

Energy-saving and efficient: With high thermal efficiency and low energy consumption, it can significantly save energy costs compared to traditional drying methods, while improving drying speed and production efficiency.

Excellent quality: During the processing, the quality of dried bananas is ensured to be consistent by precisely controlling parameters such as temperature and humidity. The dried bananas have uniform moisture content, golden color, crisp taste, and less loss of nutrients.

Easy to operate and maintain: The operation of the processing line is simple and convenient, easy to use, and the daily maintenance requirements of the equipment are low, which reduces the company’s labor costs and equipment maintenance costs.

Customized service: According to the different needs of customers, such as production requirements, product specifications, plant layout, etc., customized solutions and equipment configurations can be provided to meet the personalized production needs of enterprises.

Dried Banana Chips Production Line Related Products

—Leave A Message For A Quote—