Banana Flour Manufacturing Process Analysis: Complete Process from Raw Materials to Finished Products

Banana flour is a nutritious food ingredient widely used in baking, snacks and health foods. Its production process involves several key steps. The following is a detailed process based on multiple studies:

- Raw material pretreatment

After picking, bananas need to be washed and blemished. After peeling, the pulp is cut into 0.2-0.5 cm thick slices according to process requirements. To prevent enzymatic browning, some processes will soak in citric acid (10% concentration) or sodium sulfite (0.1% concentration) solution for 30 minutes. - Drying

Banana slices need to be dried to remove moisture. The traditional method uses a constant temperature of 60°C for 5-8 hours, while some processes use a low temperature of 50°C for 24 hours to retain more nutrients. In addition, a drum dryer can make banana flour into flakes with a surface temperature controlled at 120-130°C and further dried at 60°C for 1 hour. - Crushing and Screening

The dried banana chips are ground into Flour by a crusher (such as a hammer mill or a disc mill) and screened to the desired particle size by a sieve (such as 30-80 mesh). For example, some studies use an 80-mesh screen to ensure particle uniformity. - Packaging and Storage

The finished product needs to be vacuum-sealed and packaged to avoid moisture. The storage temperature is recommended to be 4°C to maintain quality. - Process Optimization and Innovation

Modern processes focus on the retention of resistant starch and improve product functional properties through high-temperature drying (such as 60°C) and special drying equipment (such as prototype mixing dryers). In addition, some studies have attempted to convert banana peels into calcium lactate to achieve resource recycling.

The production of banana Flour combines traditional methods with technological innovation, which not only ensures the retention of nutrients but also meets the needs of industrial production.

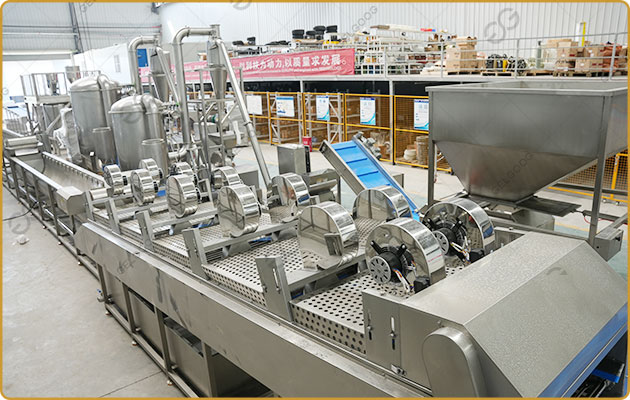

As a professional banana Flour processing line manufacturer and supplier, we are committed to providing customers with efficient and sustainable food processing solutions. Our fully automatic banana Flour production line adopts a complete process from washing, blanching, cooling, peeling, slicing, color protection, air drying, drying, grinding to packaging. If you are looking for a reliable and efficient banana Flour processing partner, please contact our professional team to explore the innovative possibilities of the food industry together!