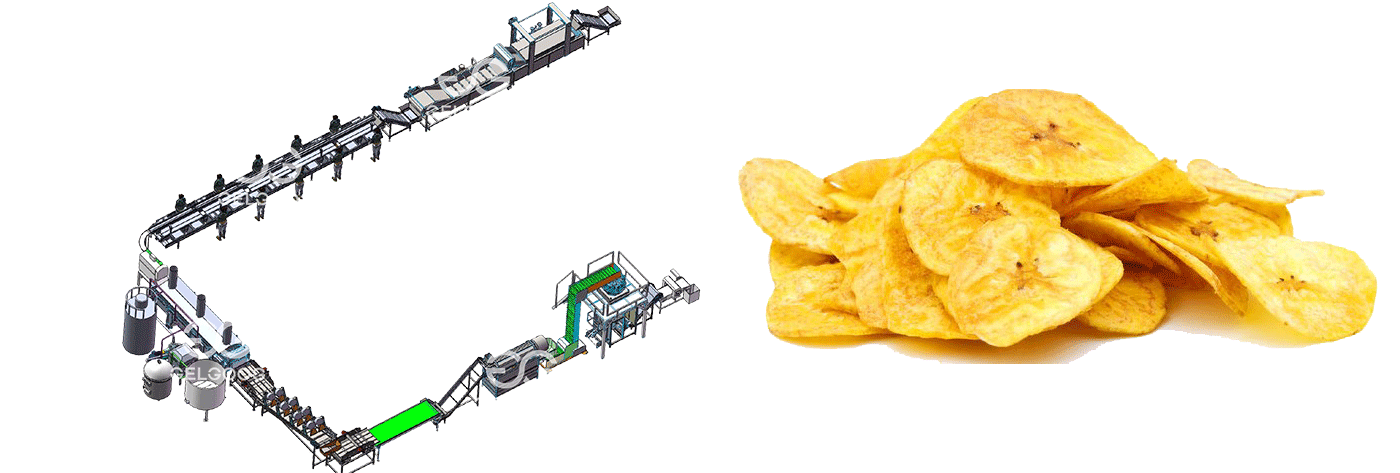

Fully Automatic Banana Chips Production Line Factory

The banana chips production line is a fully automatic production line from raw material processing to finished product packaging, covering core links such as slicing, frying, de-oiling, seasoning and vacuum packaging. The banana chips processing line is suitable for unripe bananas or plantains, and can mass-produce fried banana chips, plantain chips and other products to meet diversified market needs. The output is 100-5000 kg per hour, which can be customized according to processing needs.

Banana Chips Production Line Processing Flow

1.Peeling

2.Slicing

3.Frying

4.Deoiling

5.Seasoning

5.Packaging

- Peeling and slicing: Use a professional banana peeling machine to peel the washed bananas, and then send the peeled bananas to the banana slicer via a conveyor belt for slicing. The slice thickness can be adjusted according to customer needs, usually 2-7mm.

- Frying: The dehydrated banana slices are sent to the fryer for frying. The frying temperature is generally controlled between 160-180℃, and the time is 3-8 minutes. The specific temperature and time will be adjusted according to different varieties of bananas and the desired taste.

- Deoiling: A certain amount of oil will adhere to the surface of the fried banana slices, and a deoiling machine is needed to remove the excess oil, reduce the fat content of the product, and improve the taste and health of the product. The deoiling method generally adopts centrifugal deoiling or vibration deoiling.

- Seasoning: The deoiled banana slices can be seasoned with different seasonings according to market demand and consumer taste preferences, such as salt, sugar, chili powder, cumin powder, etc., to produce fried banana chips of various flavors.

- Packaging: Finally, the seasoned banana chips are packaged by an automatic packaging machine. There are various packaging forms, the most common ones are vacuum packaging, nitrogen-filled packaging and ordinary plastic bag packaging, etc. The packaging specifications can also be customized according to customer needs, such as small bags, family packs, gift boxes, etc.

Banana Chips Processing Line Advantage

High efficiency: The continuous production method and automated workflow greatly improve the processing efficiency of banana chips, which can meet the needs of large-scale production and produce a large number of fried banana chips in a short time, effectively improving the company’s production capacity and market supply capacity.

Low cost: The use of automated banana chips production line reduces manual operation links and reduces labor costs.

High quality: Through the refined processing of each link and precise process control, the banana chips produced have uniform thickness, consistent taste, not easy to change color, and intact nutrition, and can maximize the original flavor, original color and crispness.

Easy maintenance: The banana chips processing plant has a reasonable structure, simple operation, and is easy to clean and maintain daily, which can reduce the probability of equipment failure, ensure long-term stable operation, and reduce the company’s equipment maintenance costs and downtime.

Plantain Flour Processing Machine Related Products

—Leave A Message For A Quote—