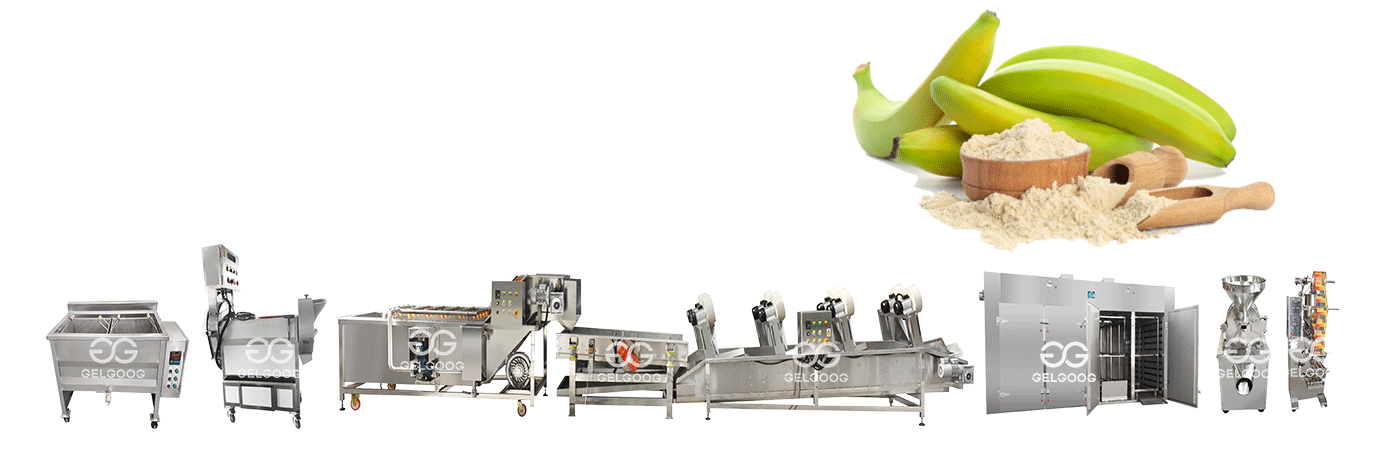

Plantain Banana Powder Production Line Plant

The industrial banana powder production line is an automated equipment designed for efficient extraction of banana starch. Plantain powder production line converts fresh bananas into high-nutrition, low-glycemic index banana powder through scientific processing technology. The core advantage of the banana powder production line is that it retains the natural nutrients of bananas and is widely used in the fields of food, feed and functional food.

Banana Powder Production Line Processing Flow

1.Peeling

2.Cutting

3.Color Fixation

4.Drying

5.Milling

5.Packaging

- Peeling: Artificial peeling can better ensure the integrity of the pulp. Currently, most manufacturers use artificial peeling.

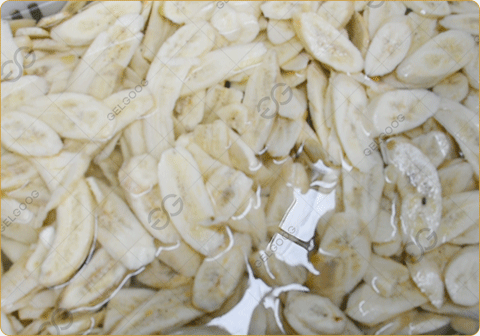

- Slicing: The peeled bananas are cut into uniform thin slices with a slicer. The thickness is generally between 2-5mm. The thickness of the slices can be adjusted according to different needs.

- Color protection: Bananas are prone to oxidative browning after slicing, which affects the product quality, so color protection treatment is required. Common methods include blanching and chemical color protection. Hot blanching is to blanch the banana slices in hot water at 90℃-100℃ for 2-3 minutes to inactivate the oxidase in them.

- Drying: Hot air drying equipment is simple and low-cost, which can effectively improve production efficiency and product quality; spray drying is to spray the banana slurry into mist through an atomizer and quickly dry it into powder in hot air, which is suitable for large-scale production.

- Crushing: The dried banana slices or blocks are crushed using a crusher to achieve the required particle size requirements. Generally, the particle size of banana powder is between 80-200 mesh, which can be adjusted according to different uses.

- Packaging: Use vacuum packaging or nitrogen packaging to package banana powder in aluminum foil bags, plastic bags or canned containers, seal and store to prevent moisture and deterioration, and extend the shelf life of the product.

Plantain Powder Production Line Advantage

High degree of automation: All links of the entire production line are basically automated, from banana washing, peeling, slicing to drying, crushing, packaging, etc., reducing manual intervention, improving production efficiency and product quality stability.

High production efficiency: The plantain powder production line runs fast and has a large processing capacity. It can complete a large number of banana powder production tasks in a short time to meet the large-scale market demand.

Good product quality: The banana powder production line can better preserve the nutrients, color and aroma of bananas through advanced drying technology and equipment. The banana powder produced is of excellent quality, delicate taste and good solubility.

Energy saving and environmental protection: Some new drying equipment has the characteristics of energy saving and environmental protection, such as heat pump dryers, solar drying equipment, etc., which reduce energy consumption while reducing pollution to the environment.

Banana Powder Processing Plant Related Products

—Leave A Message For A Quote—