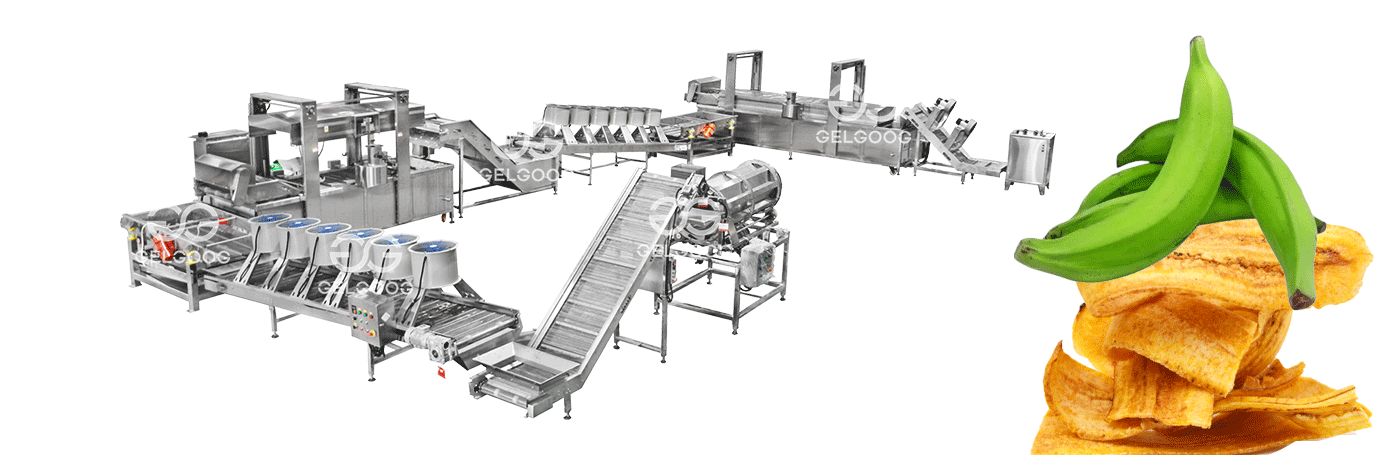

Plantain Chips Processing Line Plant 100-3000kg/H

Our plantain chips processing line is specially designed for deep processing of tropical fruits/tubers such as bananas. Plantain chips production line integrates slicing, dehydration, frying, deoiling, seasoning and packaging to achieve continuous and automated production. Unlike simple stand-alone equipment, this plantain chips processing plant adopts modular design and flexible production capacity customization (from 100kg/h to 3000kg/h), which can easily adapt to the different needs of start-ups to large food factories. It can process long and round banana chips.

Plantain Chips Processing Line Processing Flow

1.Peeling

2.Slicing

3.Frying

4.Deoiling

5.Seasoning

5.Packaging

- Raw material processing: After the green bananas are peeled by a peeling machine, they are cut into thin slices of 0.1-0.3cm thick by a slicer.

- Pretreatment: The blanching machine is used for color protection, and then enters the dehydration stage to ensure that the subsequent frying is evenly heated.

- Frying and forming: The oil temperature is 160℃ for 5 minutes to make the banana slices golden and crispy.

- Degreasing and seasoning: Remove excess oil through the degreasing machine, and then add sugar, salt or spices according to taste to enhance the flavor.

- Packaging and shipment: After the finished product is cooled, it is sealed in an independent bag by a fully automatic packaging machine to achieve efficient and hygienic finished product output

Plantain Chips Production Line Advantage

Improve production efficiency: Compared with traditional manual or semi-automatic production methods, the industrial fried banana chips processing line can process more raw materials per unit time, greatly improving production efficiency, helping enterprises to expand production scale, meet market demand, and enhance market competitiveness.

Ensure product quality: In the automated production process, the parameters of each link can be precisely controlled to ensure the quality stability and consistency of each banana chip, and can meet high standards in terms of taste, color and nutritional content, which is conducive to establishing a good brand image and winning the trust of consumers.

Reduce production costs: On the one hand, highly automated equipment reduces dependence on manual labor and reduces labor costs; on the other hand, precise temperature control and efficient frying equipment can effectively save energy consumption, while extending the service life of oil, reducing energy and raw material losses in the production process, thereby improving the economic benefits of the enterprise.

Easy to operate and maintain: The operating interface of the equipment is simple and clear, easy to learn and master, and the operator can operate the entire processing line proficiently after simple training. At the same time, the reasonable structural design of the equipment is convenient for daily cleaning, maintenance and repair, which can ensure the long-term stable operation of the plantain chips production line, reduce downtime due to failures, and improve production efficiency

Plantain Chips Processing Plant Related Products

—Leave A Message For A Quote—