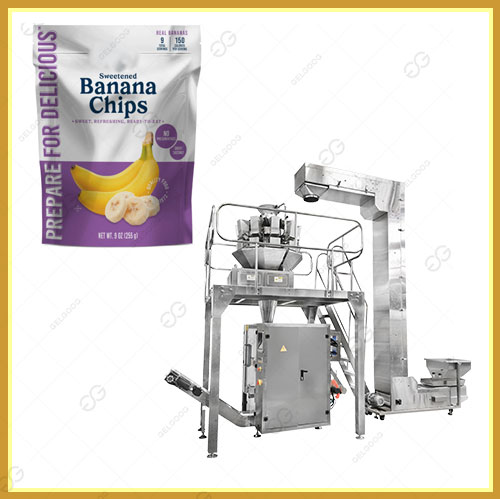

Banana chip packaging machine is a food packaging equipment that integrates automation and high precision, and is designed for granular and irregular bulk materials. The plantain chips packaging machine consists of a multi-head scale, a servo film feeding system, a sealing machine and auxiliary equipment. It can automatically complete weighing, filling, bag making, sealing, counting and other processes. Banana chips packaging machine is widely used in packaging production in the fields of puffed food, nuts, candies, dried fruits, etc.

Plantain Chips Packaging Machine Features

High precision and high efficiency: using multi-head weighing technology, the single machine capacity reaches 60 bags/minute, and the error range is ≤±0.1g, ensuring that the weight of each bag is accurate and consistent.

Intelligent operation: equipped with a programmable control system (PLC) and a large touch screen, supporting remote monitoring and parameter adjustment, easy to operate.

Modular design: compatible with a variety of packaging materials (such as plastic, aluminum foil) and sealing methods, supporting special packaging requirements such as vacuum and nitrogen filling.

Hygiene and safety: plantain chips packaging machine is food-grade stainless steel material, avoid cross contamination, and comply with international standards such as FDA and ISO.

Banana Chips Packaging Machine Parameters

| Model | GGLK1000 | GGLK720 | GGLK520 | GGLK420 |

| Film width | max 1050mm | max 720mm | max 520mm | max 420mm |

| Bag width | 100-500mm | 110-350mm | 90-250mm | 80-200mm |

| Bag length | 150-700mm | 100-420mm | 80-350mm | 50-300mm |

| Packing speed | 5-25bags/min | 10-50bags/min | 10-70bags/min | 15-80bags/min |

| Packing range | 300-5000ml | 150-4000ml | 150-2000ml | 150-1500ml |

| Film thickness | 0.04-0.10mm | 0.04-0.10mm | 0.04-0.10mm | 0.04-0.10mm |

| Power | 4.2kw/220v 50-60Hz | 4kw/220v 50-60Hz | 3kw/220v 50-60Hz | 2.5kw/220v 50-60Hz |

plantain chips packaging machine Advantages

Improve production efficiency: compared with traditional manual packaging, the efficiency is increased by dozens of times, reducing labor costs.

Guarantee product quality: standardized packaging meets export needs, reduces product loss and defective rate.

Environmental protection and energy saving: low energy consumption design, with servo system to achieve precise control, reduce resource waste.

Flexible expansion: support multi-head combination, adapt to different materials and packaging specifications.

Choosing industrial multi-head scale banana chip packaging machine can not only realize the intelligent upgrade of production process, but also win market opportunities for enterprises. Welcome to consult customized solutions and open a new chapter of efficient packaging!

Reviews

There are no reviews yet.